PRODUCT

- Contact:0536-3344577

- Contact:0536-3344677

- fax:0536-3344166

- telephone:+86-18605361716

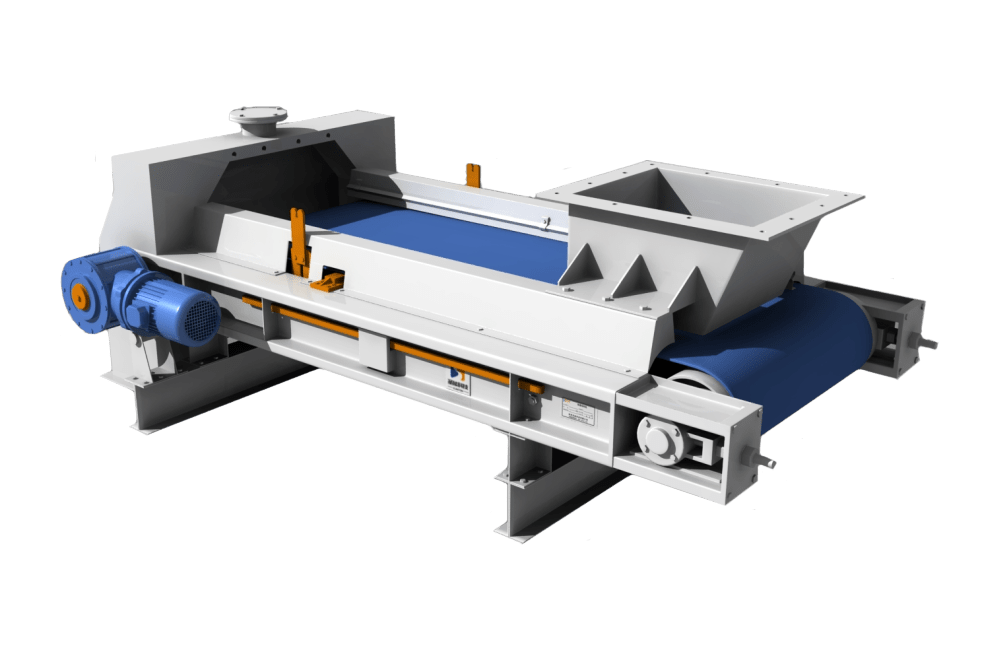

DEL/DEM Series Quantitative Feeder

The DEL/DEM type quantitative feeder is the fourth-generation variable-frequency speed-regulating quantitative feeder independently produced by our company. It is developed by introducing, fully absorbing and adopting the most advanced technologies from Schenck (Germany). All its indicators surpass those of domestic similar products and reach the international advanced level.

This feeder features high accuracy and reliable performance, and is mainly used for conveying bulk materials. Its robust design makes it particularly suitable for operation under harsh conditions. For specific working conditions, corresponding structures can be adopted to solve the most difficult problems in feeding in a cost-effective manner. It is widely applied in industries such as cement, metallurgy, chemical engineering, coal, ceramics, food, tobacco, and pharmaceuticals.

Principle

The load and speed signals of the conveyor belt are sent to a microprocessor-controlled measurement, control, and regulation system for processing. The system continuously compares the actual feeding rate with the set feeding rate, thereby controlling the speed of the conveyor belt to maintain the feeding rate at a constant level.

System Features

◆High-resolution load cells with a minimum displacement of 0.1 mm ensure accurate measurement values.

◆High-resolution digital pulse speed-measuring sensors guarantee precise speed values.

◆Automatic gravity tensioning device maintains constant belt tension, preventing belt slippage and excessive tension.

◆Automatic belt deviation correction device avoids production disruptions caused by belt misalignment.

◆Pear-shaped scrapers clear debris on the return belt to one side, preventing debris between the belt and roller surface from damaging the belt.

◆Scrapers on the inner and outer sides of the belt prevent material adhesion to the belt and changes in tare weight.

◆Belt replacement is convenient without additional assistance, simplifying maintenance.

◆Drive and driven rollers adopt self-aligning bearings, enabling very easy installation and adjustment.

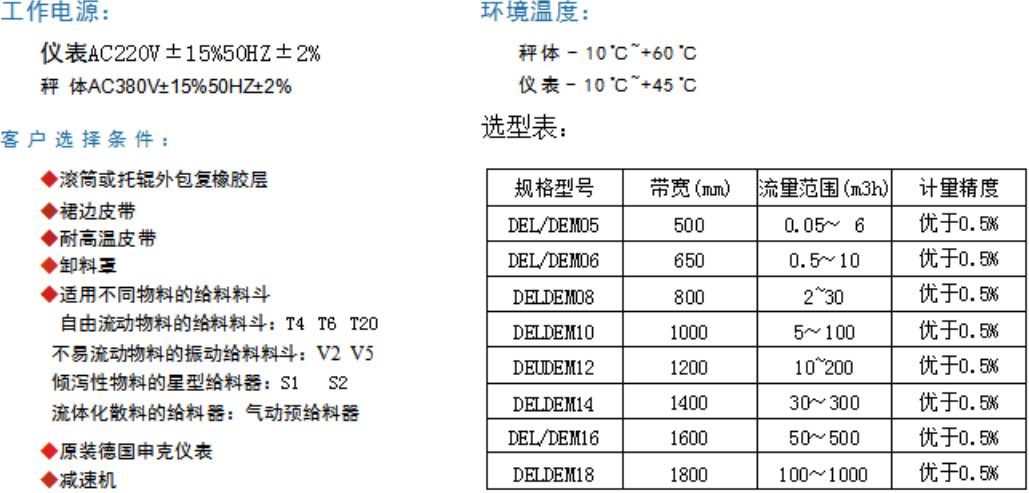

Main Technical Parameters: (In Standard Configuration)

The actual feeding accuracy for various bulk materials is better than ±0.5% of the set feeding rate.

The feeding rate ranges approximately from 50 kg/h to 2000 t/h.

Conveyor belt width: 500 mm – 1800 mm.

Drum center distance: 1300 mm – 5000 mm, using a plug-in system.

Output interface: multiple options available, can be connected to a DCS system.