PRODUCT

- Contact:0536-3344577

- Contact:0536-3344677

- fax:0536-3344166

- telephone:+86-18605361716

:

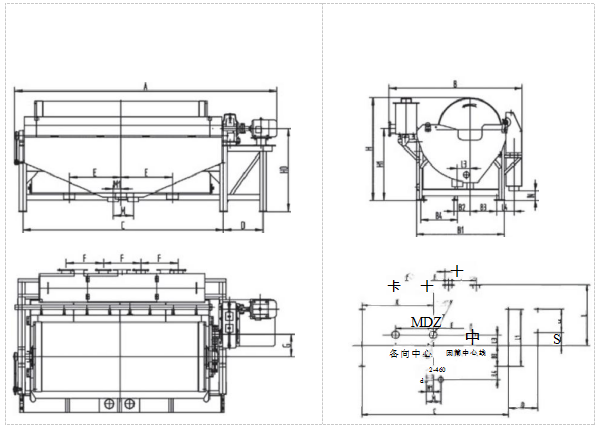

CTB Semi-Counterflow Magnetic Separator

Overview

The Permanent Magnetic Drum Separator is suitable for the wet magnetic separation of materials with a particle size of less than 3mm, such as magnetite, pyrrhotite, roasted ore, and ilmenite. It is also used for iron removal operations in materials like coal, non-metallic minerals, and building materials.

The magnetic system of the Permanent Magnetic Drum Separator is made of high-quality ferrite materials or compounded with rare-earth magnetic steel, with an average magnetic induction intensity of 100~600mT on the drum surface. According to user requirements, it can provide various types of magnetic separation with different surface intensities, including concurrent-flow, semi-counterflow, and counterflow models. The Permanent Magnetic Drum Separator has the advantages of simple structure, large processing capacity, easy operation, and convenient maintenance. The applicable feed particle sizes of the three magnetic separators with different tank bodies are as follows:

Concurrent-flow tank body: 6-0mm

Counterflow tank body: 1.5-0mm

Semi-counterflow tank body: 0.5-0mm

Magnetic separators can be classified into low-magnetic, medium-magnetic, and high-magnetic separators based on magnetic field intensity. By separation method, they are divided into dry magnetic separators and wet magnetic separators. According to the method of generating magnetic fields, they fall into electromagnetic magnetic separators and permanent magnetic separators. In terms of different structures, they include barrel-type, disk-type, roller-type, ring-type, rotating roller-type, rotating cage-type, and belt-type magnetic separators, etc. The magnetic separators produced by our company are mainly permanent magnetic barrel separators, dry magnetic separators, and double vertical ring pulsating high-gradient magnetic separators.

Performance Features:

1、The magnetic field distribution is reasonable, and there is no demagnetization even after long-term use;

2、The tank body is designed with computer-simulated fluid dynamics, which effectively prevents pulp sedimentation and blockage;

3、The magnetic system is easy and reliable to adjust, with no magnetic leakage to the main shaft. The bearings operate stably and have a long service life.