PRODUCT

- Contact:0536-3344577

- Contact:0536-3344677

- fax:0536-3344166

- telephone:+86-18605361716

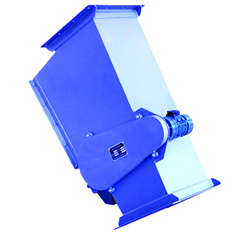

RCYG Pipeline Self-Discharging Iron Remover

Features:

★ This equipment uses neodymium-iron-boron (NdFeB) with high residual magnetism as the magnetic source, featuring high iron removal efficiency and a long service life.

★ The power source adopts a low-power cycloidal pinwheel gear motor, and the transmission uses a precision roller chain. It has the advantages of small size, light weight, reliable and stable operation, and few faults, making it convenient for users to operate and easy to maintain.

★ The equipment has a reasonable and compact structural design, and is easy to install. It can be used directly after being connected in series to the material conveying pipeline.

★ The iron removal process is continuous and automatic, requiring no supervision after the equipment is started.

★ It is suitable for closed material conveying systems, with no dust emission during operation and no environmental pollution.

★ The pipeline wall is made of special wear-resistant materials, which doubles the service life.

Working Principle:

The iron remover is connected in series to a material conveying pipeline with an inclination angle of 45°~75°. When materials pass through the iron remover, the ferromagnetic substances contained in them are adsorbed onto the manganese steel pipe wall of the pipeline iron remover. These ferromagnetic substances gradually slide toward the iron outlet as the permanent magnet moves, realizing separation from the materials. At the iron removal position, the permanent magnet moves away along the circular motion direction, causing the ferromagnetic substances to lose magnetic attraction. Under the action of gravity, the ferromagnetic substances are discharged from the iron outlet, thus achieving automatic iron removal from the materials.

Main Technical Parameters:

Model | Adaptive Output T/h | Pipeline Overall Dimensions A×B×C mm | Flange Interface Dimensions mm | Adaptive Slope | Working Mode | Motor Power kw | Weight kg | Adaptive Particle Size mm |

RCYG-3 | 100 | 1450×300×600 | 350×350 |

55°~66° |

Continuous and automatic |

0.55 | 175 |

≤25 |