PRODUCT

- Contact:0536-3344577

- Contact:0536-3344677

- fax:0536-3344166

- telephone:+86-18605361716

CTQ Roller-Type High-Intensity Magnetic Separator

I.Explanations

◇It adopts a new type of special rare earth permanent magnet material, featuring ultra-high magnetic field strength and high magnetic field gradient. The number of magnetic rollers can be customized from 1 to 10 according to customer requirements.

◇High-strength and ultra-thin conveying and sorting belts are used. The magnetic rollers are protected by the conveyor belt, ensuring no wear and tear and resistance to demagnetization.

◇An independently designed feeding system ensures more uniform feeding, allowing for timed and quantitative control of feeding at any time. It is equipped with a simple and practical self-weight flat belt tensioning and deviation correction mechanical device.

◇A new type of axial series-pole repulsion magnetic system structure is adopted. Compared with electromagnetic high-intensity magnetic separators, the magnetic induction intensity on the surface of the magnetic roller has a magnetic field gradient that is 3-4 times higher.

◇There is no air gap, and materials will not be blocked. The maximum size of feedable materials can reach 50mm, and the sorting efficiency is high. It has low installation, maintenance and production operation costs, and is easy to operate.

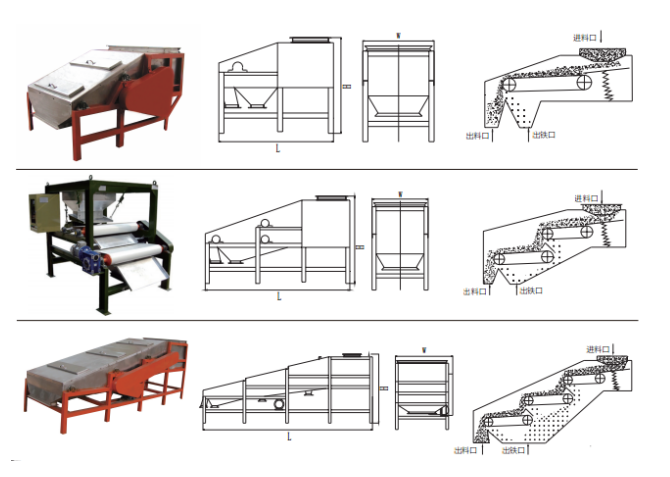

II. Schematic Diagram

III. Application Scope

It is mainly applied to the tailings discarding or concentration purification of fine-grained weakly magnetic minerals (such as limonite, manganese ore, etc.); the refined processing of raw materials and products of non-metallic minerals (such as andalusite, sillimanite, kyanite, garnet, feldspar, quartz, rutile, zircon, corundum, diamond, etc.); and the removal of weakly magnetic harmful impurities from various abrasive products, catalysts and other materials.

IV. Main Technical Parameters